Remember that “capacity crunch” everyone has been talking about for the last couple of years? Judging by this month’s elevated rates, you would think the crunch had already begun.

Brokers don’t seem to be panicking, however. They are still finding trucks. In fact, even as rates surged towards record highs in June — after a drop in April and May — spot market capacity continues to meet the challenge.

HOS drove rates up, beginning last Fall. As the ramifications of the new HOS rules became apparent, rate trends moved in an unexpected direction. Instead of a sharp decline following the typical June peak, rates hit a plateau in July 2013. At the time, I noted that short term trends showed about a 1.5% rate impact due to HOS, even though industry experts noted a productivity loss of 3.3% to 5.0% as a result of the new rules.

Rate increases weren’t compensating for lost productivity. The trucking industry overall couldn’t support that 1.8% to 3.5% give-back, and still do business as usual. Carriers began to scale back. Big fleets canceled expansion plans and tractor purchases, and some of the more marginal fleets and owner-operators exited the industry altogether.

Then the bad weather hit. Usually rates decline sharply right after Thanksgiving. In the winter of 2013, rates soared instead. December was just the beginning. The first quarter of 2014 saw storm after storm buffet the Midwest and Northeast, then ice and snow clobbered Atlanta and the Southeast — not once, but twice.

Trucks were immobilized by snow and ice, reducing productivity even further for contract carriers. A lot of that freight was re-scheduled, and more loads than ever found their way to the spot market, contributing to record volume in what is usually the slow season.

Intermodal could not pick up the slack. Shippers and 3PLs also sought rail intermodal options, but no mode was immune to the severe weather. By March, rail traffic was being diverted back to trucks in many cases, adding to the intense pressure on rates.

Truck shortages have been predicted for quite a while. GDP growth of 2.8% or higher was the tipping point anticipated by Bob Costello, chief economist of the American Trucking Associations. Mr. Costello, an extremely knowledgeable industry analyst, cautioned that the additional demand would lead to truck shortages.

Transportation didn’t perform in Q1 as expected. Even though GDP contracted by 2.9% in the first quarter, the weather disrupted supply chains and sidelined trucks, so regional shortages had widespread but temporary impact.

In Q2, economic expansion is boosting GDP. Economic growth appears to be on track to exceed 3.0% for this quarter. That beats Mr. Costello’s threshold, but reports of severe shortages have not materialized.

Are trucks tight? Absolutely. Many markets are challenged. Yes, you will have a hard time booking a flatbed in Memphis or a reefer in southern Georgia. I would not want to be a truck finder today, facing those conditions. In most other circumstances, however, you can probably find a truck. You may have to pay more than you expected, but trucks are available.

So what went right? A lot of freight brokers and 3PLs went both wide and deep to find capacity over the past eleven months. Carriers adjusted their schedules, using more relays, teams, alternative routes and other creative means to offer drivers more time at home, so the fleet could keep more trucks on the road and prevent an increase in driver turnover. So far, so good.

Where are the dire truck shortages that analysts predicted? I don’t see widespread shortages just yet. There are two main reasons: First, despite the additional demand, the spot market has been able to deliver capacity. The second factor is rail, which has grown its share of the market just enough to act as a release valve, siphoning off that last bit of pressure that could otherwise blow the lid off domestic freight transportation.

Spot market capacity has expanded somewhat, as well, due to high rates that attract additional carriers. The new capacity is not yet sufficient to exert downward pressure on rates, at least during the busy season, but trucks are available where they are needed, with severe shortages at only a few origins.

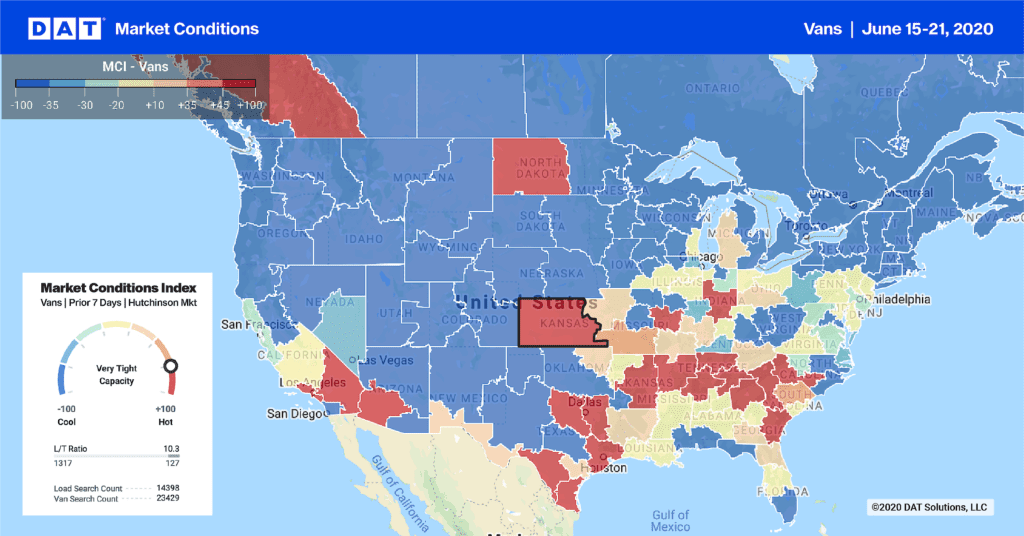

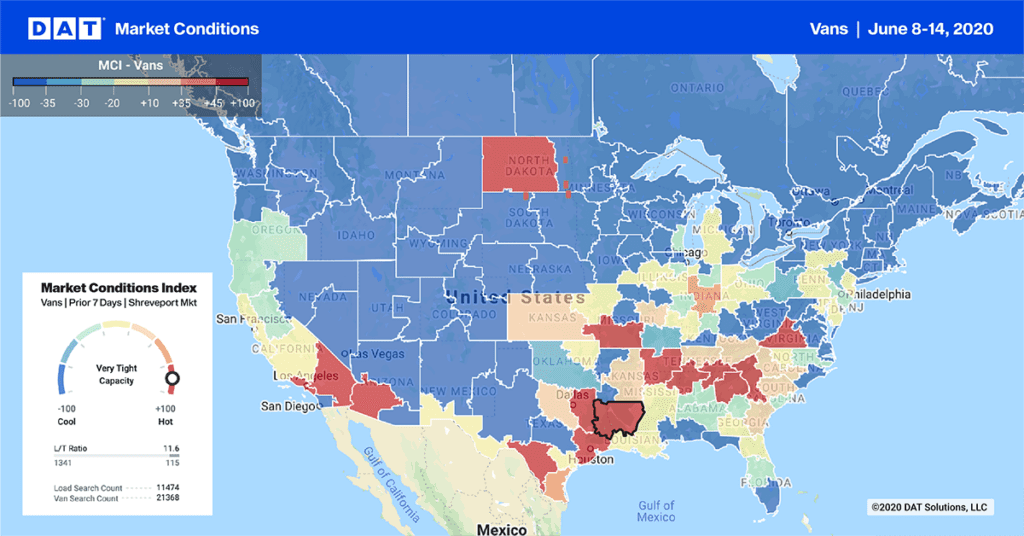

Which lanes are challenged and where is capacity abundant? Changes in rates point to changes in capacity, especially in high-volume freight markets. For example:

- CHALLENGED: Houston, Memphis, and Phoenix are very tight for vans.

- BUSY: Atlanta, Charlotte, and Columbus are busy, but with trucks available.

- QUIET: Chicago, Denver, and Seattle, on the other hand, have plenty of trucks.

Overall, I see a tight market for truckload transportation, but the freight continues to move, despite the challenges.

DAT RateView and DAT Load Boards help transportation and logistics professionals to manage brokers, carriers, and shippers to manage exception freight, with analytic tools that illuminate trends in demand, capacity and rates. Harnessing years of historical data, alongside a detailed view of current conditions, savvy transportation pros can improve profitability and develop more accurate forecasts.