Large retail companies routinely pay a premium for trucking capacity and consistency, according to comments by transportation managers at a NASSTRAC best practices workshop on managing transportation capacity and costs. That’s because delivery schedules often take precedence over cost considerations, or as one logistics exec said of his internal customers: “They call, we haul.”

Accurate forecasting is especially critical for grocery chains, whose profit margins are slim, or whose transportation and costs are high relative to profits. In the grocery business, much of the inventory is perishable, seasonal or both, adding risk to any disruption of their delivery schedules.

In addition to annual rate adjustments, which are included in the normal budget cycle, transportation managers worry about the effect of “wild card” factors such as unseasonable weather and ever-changing fuel prices. Natural disasters like Hurricane Sandy cause obvious and costly disruptions to the supply chain, but small, localized weather events can also wreak havoc on transportation schedules and budgets. Logistics managers have contingency plans in place for large-scale events, but they also need a constant stream of actionable information to help them adapt to new situations as they arise.

A very large retailer may have access to that type of information, but many other shippers have already reduced staffing levels in their transportation and logistics departments due to recession-related budget cuts. With fewer in-house pros available, shippers become more reliant on brokers and 3PLs, especially when freight volume exceeds their original forecast.

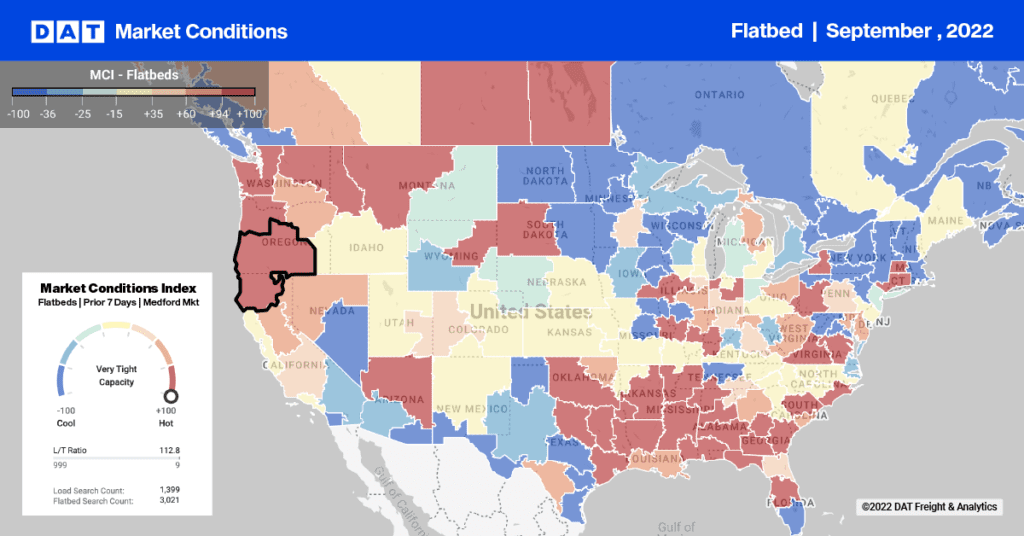

The shipper pays for brokerage and 3PL services, and the best intermediaries provide a lot of value for the money, well beyond just securing a truck. An intermediary with access to DAT RateView, for example can help shipper customers to budget for contingencies, using historical lane rates and demand patterns to predict future rates with a high degree of accuracy, suggesting alternative routes, timing and other trade-offs that can save money or accomplish other key goals.

Armed with this actionable information, the shipper will be able to plan even for unknowable factors like the weather and fuel prices, based on a robust, mutually beneficial relationship with the knowledgeable intermediary.