Following the introduction of the USMCA in 2020, many believed trade between the U.S., Canada, and Mexico would flourish. However, the resurgence of tariffs — despite this free trade agreement — has raised eyebrows. These tariffs have taken many by surprise given the depth of economic integration between the U.S. and Canada.

According to our data, dry-van spot-market volumes from Toronto to Chicago increased by 57% during the week ending February 28, while rates in this cross-border lane rose by 7%. On the afternoon of Monday, March 3, U.S. President Donald Trump confirmed that the 25% tariffs on goods imported from Canada and Mexico would take effect as planned on March 4. The anticipation of these tariffs, along with the potential for reciprocal measures, is already influencing freight activity and pricing on both sides of the U.S.-Canada border. Spot rates from the U.S. to Canada, on average, have climbed 18% since the U.S. elections and 6% in the last two weeks to their highest level in two years.

If you’re a U.S.-based business, understanding these dynamics is critical and a bit opaque in terms of downstream effects. This is an evolving situation. Here’s what you need to know.

Key industries feeling the impact

The automotive sector

The auto industry is arguably the most affected by these tariffs. The added tariffs are expected to increase vehicle costs by thousands of dollars, further straining consumer demand, which remains well below pre-2018 levels.

The intricacies of the automotive supply chain also exacerbate the problem. Tariffs are being levied at multiple stages of production, inflating costs. For example, a U.S. company receiving auto parts from Canada may pay a tariff upon import, only to export the same parts back to Canada later—a process that has no provision for duty relief. Steel haulers in the automotive sector in Ontario believe that specific minerals and resources will continue to move cross-border such as aluminum.

Agriculture and food exports

Agriculture is another key area of concern. Consider:

- Soybeans now face tariffs from China, which had previously delayed such measures during initial trade discussions. This has already led to a sharp decline in soybean exports, forcing the U.S. government to provide $23 billion in aid to farmers.

- Corn exports, especially to Mexico and Canada — two major destinations for U.S. goods — are now at risk of shrinking further. Retaliatory tariffs from Canada only heighten this risk.

Producers in Brazil are already seizing the opportunity to replace U.S. agricultural exports, with China sourcing increasing amounts of its grains from South America. This long-term shift away from U.S. markets could deepen the challenges for American farmers.

Metals and manufacturing

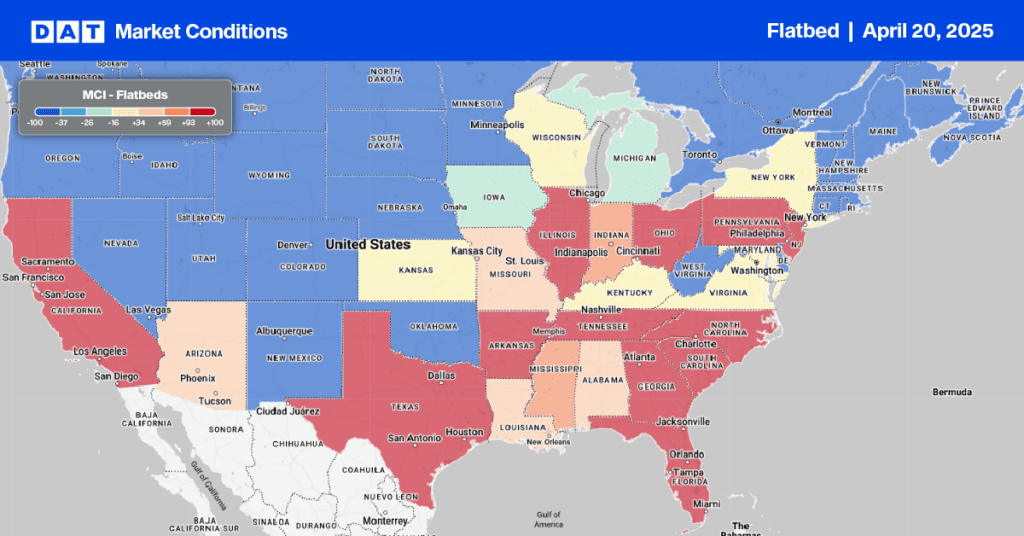

Steel and aluminum tariffs are another major factor. These increases not only burden manufacturers who rely on these materials but also make U.S. goods more expensive and less competitive globally. A case study of steel tariffs from the early 2000s revealed that such measures made U.S. businesses significantly less competitive, with countries like Germany, France, and Japan benefiting the most by picking up lost U.S. market share.

Analysts worry current tariffs risk repeating history, disrupting supply chains and raising costs for downstream industries reliant on these raw materials.

Consequences

Short-term volatility

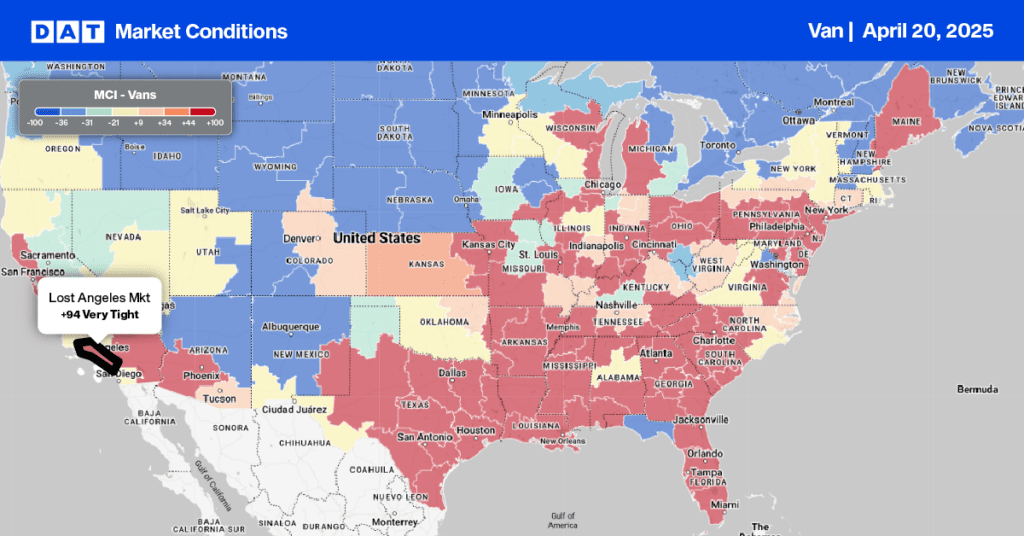

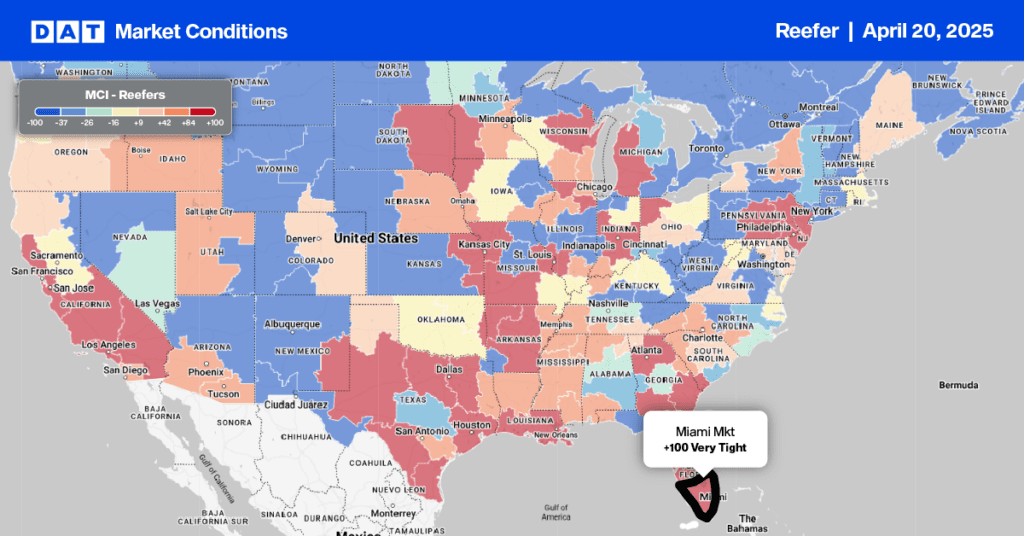

The sudden implementation of tariffs has led to immediate disruptions. Freight carriers are demanding higher rates, contract loads are falling through, and brokers are scrambling to adjust. For businesses, these short-term challenges translate into higher transportation costs and delayed shipments, negatively affecting their bottom line.

Freight rates have been volatile, with instances of rates doubling in the face of increased demand to move goods before tariffs took effect. Brokers are reporting an inability to cover loads as shippers push to transport inventory across borders. One broker we spoke with in Ontario said load rates have doubled in the last week as carriers seek round-trip rates not knowing if they’ll be able to get a load back to Canada from within the U.S. This type of volatility is not sustainable in the long term and could lead to systemic inefficiencies in supply chain operations.

If a large portion of the estimated 75% of Canadian carriers involved in cross-border freight are forced to seek work domestically (as cross-border volumes decrease), those fleets are going to downsize drastically or be forced out of business if the trade war drags on.

Long-term shifts in trade relationships

Perhaps the most concerning impact of these tariffs is the potential for long-term damage to trade relationships. Historical data shows that when tariffs are implemented, affected countries often seek alternative trading partners. China’s growing reliance on Brazilian agricultural products is a prime example of this trend. Without swift action, U.S. businesses could face a slow but steady erosion of their export markets, particularly in sectors like agriculture and manufactured goods.

Demand destruction

Another significant risk is demand destruction — when the added costs of tariffs reduce the overall demand for a product. Higher vehicle prices, for instance, are likely to deter buyers at a time when the auto industry is already vulnerable. Similarly, higher costs for metals and agricultural goods could make them less attractive to foreign buyers, further reducing demand for U.S. exports.

Navigating the new landscape

For U.S. businesses that rely on cross-border trade with Canada and Mexico, understanding and adapting to these changes is crucial. Here are a few strategies to consider:

- Diversify supply chains: Explore sourcing options beyond Canada and Mexico to reduce exposure to tariffs.

- Negotiate freight contracts: Lock in rates with freight carriers to mitigate the impact of price volatility.

- Focus on internal efficiencies: Invest in technology and process optimization to offset increased costs associated with tariffs.

- Monitor policy changes: Stay informed about potential policy shifts, as tariffs and trade agreements remain dynamic.

These adjustments can help businesses weather the immediate challenges and position themselves for long-term resilience.

Resources

Government sources

Harmonized Tariff Schedule (HTS) – U.S. International Trade Commission – The official resource for looking up U.S. tariff classifications.

U.S. Customs and Border Protection (CBP) – Provides details on tariffs, import regulations, and trade enforcement policies.

Office of the U.S. Trade Representative (USTR) – Publishes official tariff announcements, trade agreements, and negotiations.

Industry sources

American Association of Exporters & Importers (AAEI) – Focuses on customs and trade regulations, including tariffs.

U.S. Chamber of Commerce – Advocates for businesses on trade policies, tariffs, and global commerce.

National Association of Manufacturers (NAM) – Represents manufacturers and provides updates on tariffs affecting the industry.

Transportation & logistics associations

National Customs Brokers & Forwarders Association of America (NCBFAA) – Covers tariff policies affecting customs brokers and freight forwarders.

Agricultural Transportation Coalition (AgTC) – Addresses tariff impacts on agricultural exports and logistics.