DAT iQ recently spoke to lumber and housing expert Dustin Jalbert from Fastmarkets to better understand flatbed demand, particularly in the single-family construction market.

Dean Croke (DC): Residential construction numbers for August were just released this morning by the U.S. Census Bureau. Are you surprised by the 4% decrease in single-family housing statistics?

Dustin Jalbert (DJ): We don’t view the August numbers as too much of a shock. When we look at single-family starts, it tends to be volatile month to month. So, being down 4% m/m was not a huge shocker, especially if you look at a three-month rolling average, which smoothes out the volatility. Single-family starts are bouncing off the bottom we saw earlier in the year, resulting from the interest rate shock we’re experiencing. Permit numbers were up 2% m/m, which indicates buoyant future demand. So, considering the sweltering conditions in the U.S. South, from Texas to Florida in August, it’s no surprise to see builder productivity adversely impacted. The story is still one of recovery, but maybe some deceleration in single-family starts has us a little concerned.

DC: Compared to this time in 2019, which was a very similar freight market to this year, last month’s housing starts were only 30,000 higher than in 2019. Can we compare and contrast those two years? We see a lot of similarities between freight demand in 2019 and this year.

DJ: Two-thousand nineteen was a challenging year for the housing and wood products markets. We also had a significant interest rate shock in 2018 when the Fed raised interest rates four times, leading to a slowdown in building activity for single-family starts four to six months later. Then, in 2019, they cut interest rates three times to give the economy a fresh boost.

The rate shock we’re facing right now is borderline historic; something like a 500 basis points increase in 12 to 18 months. It is impressive that housing starts, especially on the single-family side, have been as resilient as they have been. And that does say something about the health of the household balance sheets of the consumer. There is a shelter shortage coupled with the millennial cohort that wants to step into homeownership.

So those factors are keeping things afloat, along with builders being very aggressive with incentives, particularly interest rate buy-downs on the mortgages. So even though the prevailing mortgage rate did something between 7.0% to 7.5%, builders offer buyers 5.0% to 6.0%, which makes a big difference in pulling people into new homeownership.

DC: On the show last year, when you first came on, you surprised us with the amount of demand you attributed to repair and remodeling. It was around 40% at the time – has that changed a year later?

DJ: It’s still around 40% after jumping to 45% during COVID when everyone was stuck at home using their stimulus checks to dive into repairing and remodeling their existing homes with one-off projects. Since then, demand in this sector has come back down closer to 40%. And some of that is just a reflection of people who are back participating in the service side of the economy. Some of that, you know, those decks in those sheds and those fences, that activity was pulled forward into 2020 to 2021. But it’s still a significant share of the market overall. Smaller, medium-sized projects have come off, but people are still taking on those significant major renovations for $50,000.

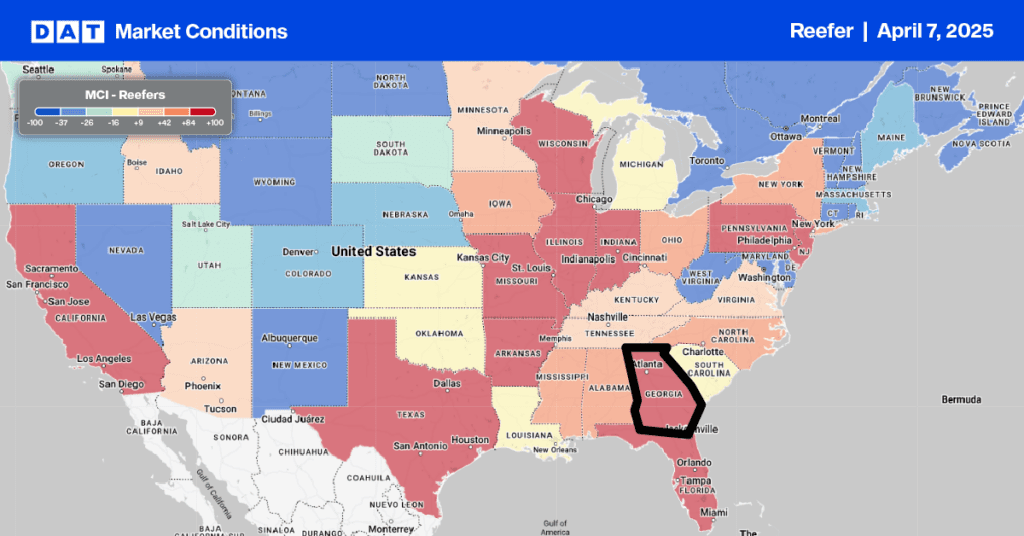

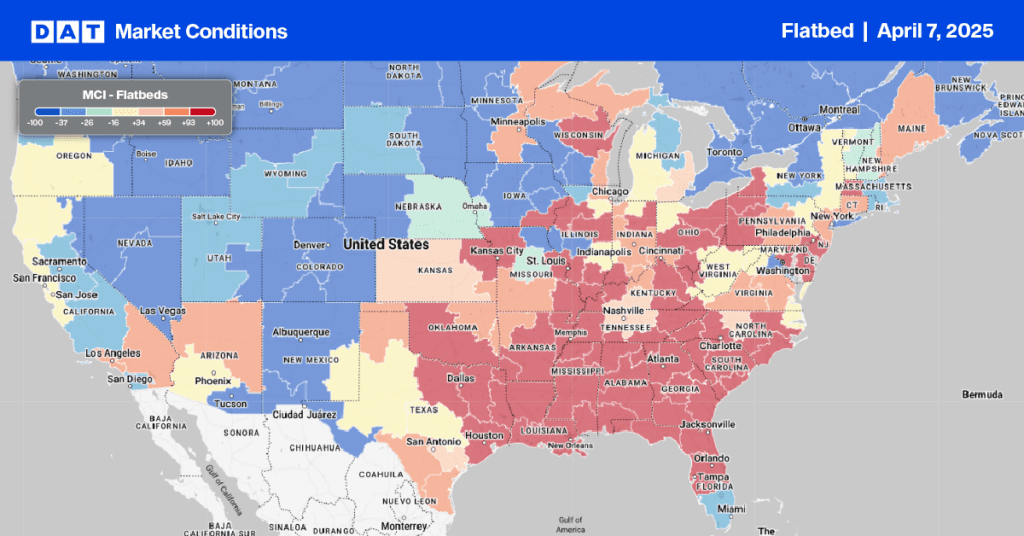

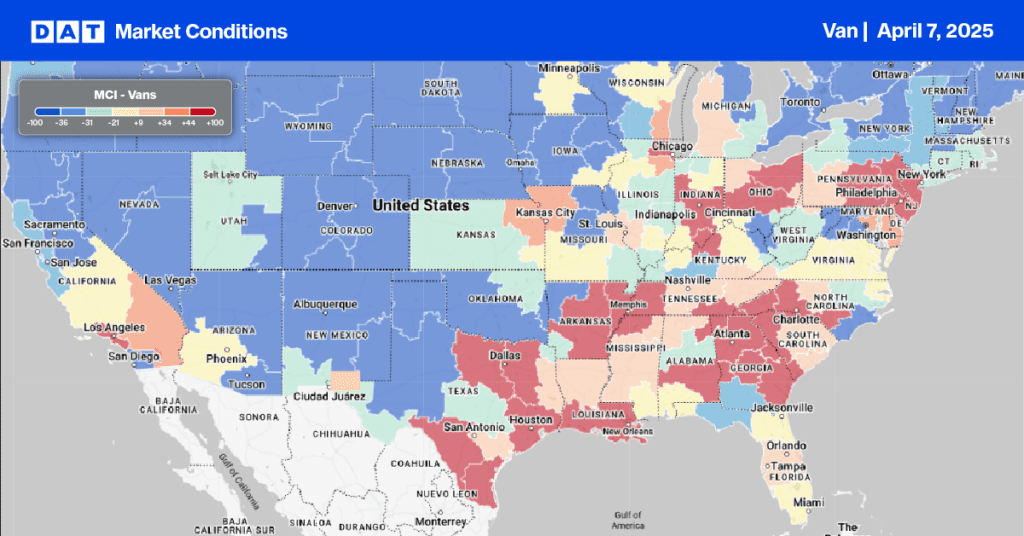

DC: When we look at flatbed demand, we typically see solid flatbed demand in three regions – Quebec/Northern Maine, the Southeast, where about 63% of single-family homes are started each month, and then another pocket in the Pacific Northwest, mainly in Portland and Medford markets. Can you speak to some of the sawmill inventory levels and some headwinds they face regarding freight demand?

DJ: You’ve listed three or five significant producing regions of softwood dimensional lumber and other wood products like OSB plywood and engineered wood products. At a more macro level, inventories are increasing, and the lumber market prices have slipped into the doldrums. Although they’re still above pre-pandemic levels, they’re pressing on production costs for the high-cost suppliers, which is really in Canada and the Pacific Northwest. So they’re in a tough spot because prices are unfavorable. So, inventory must still be worked on in the U.S. and Canada.

The complete interview with Dustin Jalbert can also be found here.