My local farmstand proprietor in New England told me last week he had considered not selling Christmas trees this year due to recent drought conditions and the substantial impact on cash flow. In this case, the business owners had to place their 2023 order of trees in August and pay in complete, causing an enormous drain on cash flow.

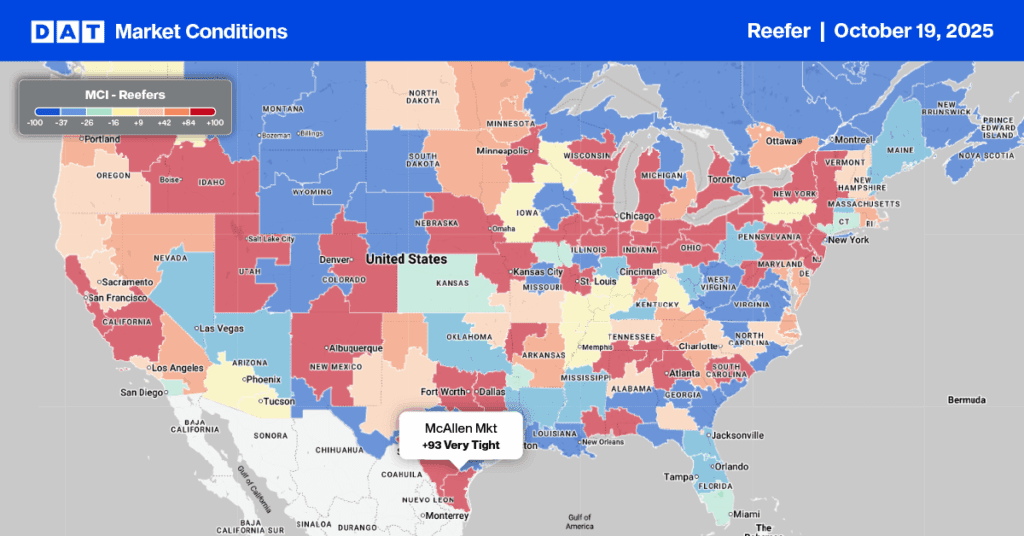

On top of that, transportation costs from Nova Scotia to New England will be much higher this year due to drought conditions in Maine nine years ago, their typical source of Christmas trees and about one-quarter of the distance from Canadian farms and one-third of the freight cost. According to DAT’s Ratecast, Reefer loads from Nova Scotia will cost around $2,300/load compared to regional loads from southern Maine, which average $800/load by the time we get to Christmas week.

When does peak shipping season for Christmas trees occur for truckload carriers?

Peak shipping typically occurs in the weeks leading up to Thanksgiving and continues through December. The U.S. Capitol Christmas Tree signifies the start of the shipping season, with this year’s tree, a 63-foot Norway Spruce, making the 250-mile haul from the Monongahela National Forest in West Virginia starting November 4. This year, Werner Enterprises (NASDAQ: WERN) has been chosen to transport the 2023 tree.

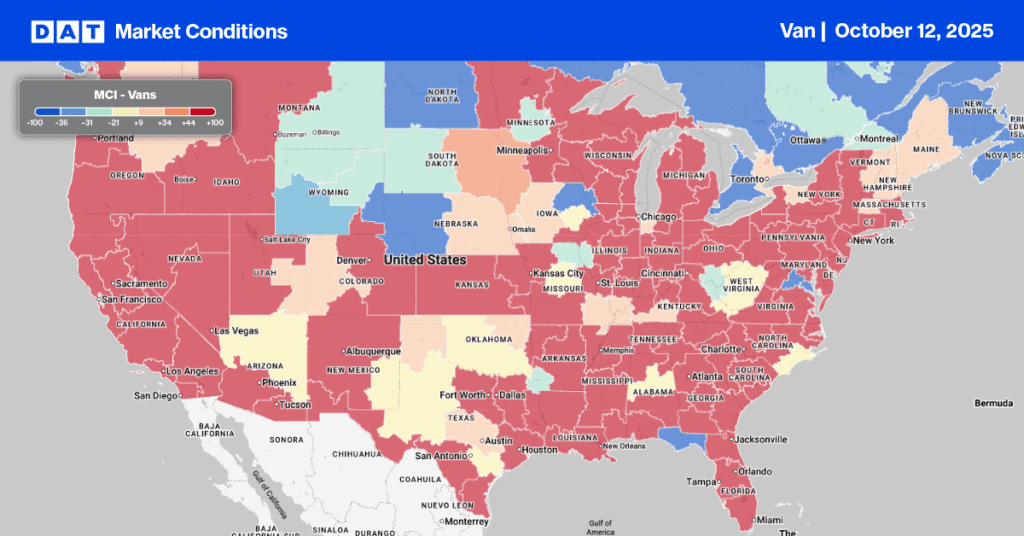

Around the same time, the high-volume shipping season in the Pacific Northwest (PNW), where most trees are produced, begins with pine trees being shipped to manufacture holiday decorations, followed by trees bound for Hawaii loaded into containers in the first week of November. The week before Thanksgiving is the busiest time of year when most loads move to Texas, California, and other Western states.

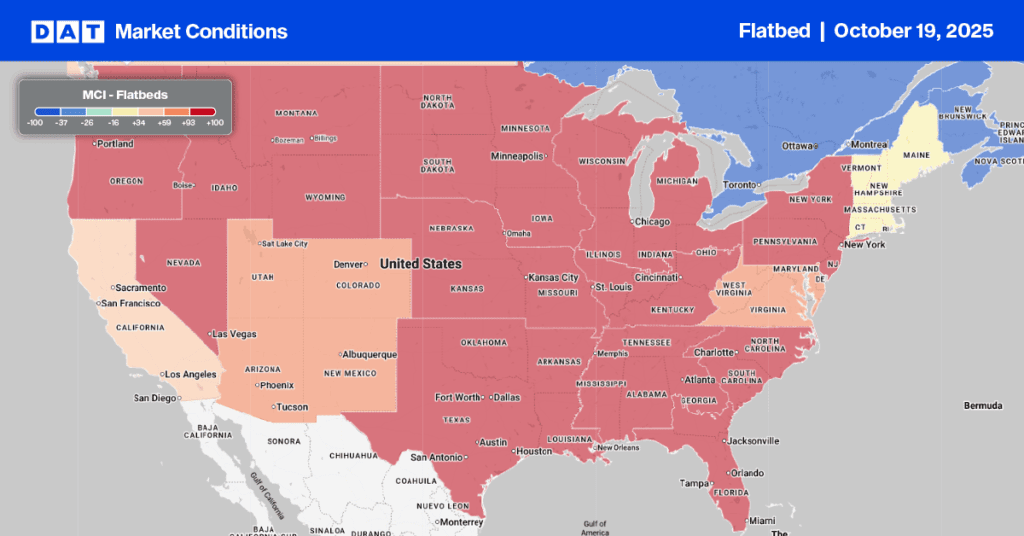

According to the Pacific Northwest Christmas Tree Association (PNWCTA), Oregon and North Carolina account for just over half of the 25-30 million trees harvested nationwide. Oregon is the market leader in production, with 92% of trees exported from the region, mainly to California (45%) and Mexico (16%). The Christmas tree harvest coincides with the peak season for Fall produce in the PNW, including potatoes, onions, pears, and apples, to name a few, which results in tight capacity and rate increases out of critical markets, including Oregon and North Carolina.

Reefer, dry van, or flatbed?

For carriers and brokers, it’s a short shipping season characterized by remote loading locations involving helicopters, specialty trailers, and urban deliveries with multiple drops – not the easiest freight to haul. According to the PNWCTA, “The goal of every grower is to see that trees cut today are on the highway the same day en route to customers within hours of when they were harvested.”

Shorter haul loads from Washington and Oregon to California can go in a dry van, but anything to the Midwest or East Coast requires a reefer to protect the trees from heat and freezing.

Some customers want ice blown over the top of the trees to keep them cold and prevent them from drying out, although some customers only want dry vans, even on such a long trip. They believe the air from the reefer unit dries the trees out, and the airflow chute limits the number of trees that will fit in the trailer.

For truckers, hauling Christmas trees is nothing to celebrate.

DAT Freight & Analytics spoke to drivers hauling trees from the Canadian Pacific Maritimes. Trailers dropped at tree farms for pre-loading can be loaded in 24-36 hours, but unloading 800 trees can take two to three days. According to Bobby McDonald, an owner-operator with K&S Trucking in Sydney, Nova Scotia, “It all depends on how many people are there to help unload. Trees are mostly floor-loaded, so they must be loaded and unloaded by hand. It can take 3 to 4 hours to unload 400 trees, but here in New Jersey, it only took an hour to unload 428 trees this week. Throwing 11 workers at the load certainly made a difference.”

A lot of loads will involve multiple drops at small retail outlets, farm stands, and car parks, and that’s the time-consuming aspect of hauling Christmas trees. For regional haul loads from Oregon to California or Nova Scotia to New Jersey, it’s less about the rate per mile and more about the number of days a truck and trailer are under the load.

In many cases, that can easily be four days and up to six for multi-drop loads. On top of that, drivers have sap and pine needles to deal with while getting home on time for the holiday break.