Without a deep well of data, forecasting falls apart immediately. For example, in the transportation industry, some models attempt to compensate for the absence of true supply-and-demand metrics by using secondary data like tender acceptance and rejections as a way to proxy truckload capacity. They then adjust their predictions based on that data’s relationship with the current rate trend.

That methodology predicts rates with an accuracy in the range of plus-or-minus 17 cents per mile. If the actual rate per mile lands between $1.50 and $2, excluding fuel, then a 34-cent range does not provide useful guidance, regardless of the timeframe.

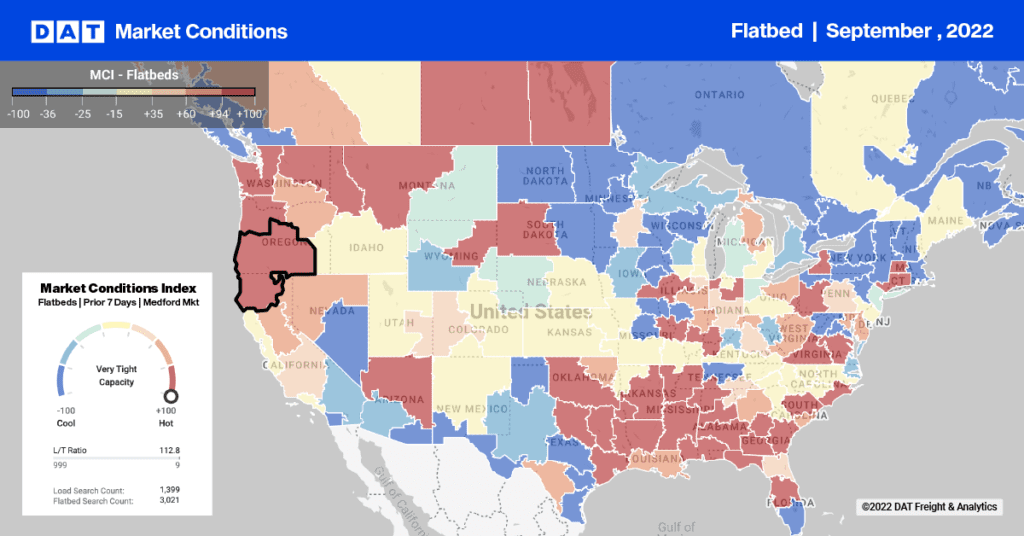

The DAT iQ team set out to create a forecasting model that would produce more actionable results. A major advantage was direct access to supply and demand data from the DAT One network, North America’s largest trucking marketplace.

The DAT iQ team also leveraged the unmatched breadth and depth of the RateView database, the most historically complete rate database on the market. With more than 10 years of historical records, the RateView database includes $1 billion in invoices collected on 88 million transactions.

With this firm foundation, the team then set on choosing the most appropriate algorithm to account for variability.

Day-of-week bias

When building a freight forecasting model, the algorithm has to account for the day of week, where that day lands in the month, where that week lands in the year and many other timing factors.

For one, truckload rates have a strong day-of-week bias — prices on Mondays tend to be higher than Tuesdays. Days at the beginning and end of the month, especially near the end of the quarter, also affect prices. Predictions also have to create exceptions for holidays.

Seasonality plays a major role as well. Dry van and refrigerated rates are strongly influenced by produce harvests, though the influence is stronger on some lanes than others and happens at different times of the year for specific markets. Back-to-school shopping, holiday season, Chinese New Year and even events like annual safety inspection blitzes also affect each lane differently.

An effective forecasting model knows these trends – and knows when they’ve been disrupted.

Learn what innovative freight intelligence can do for your bottom line. Download the full Power of Prediction white paper.