What can shippers do to make their freight attractive to carriers? Three shippers answered that question during a panel discussion at the 2018 DAT User Conference in Portland, OR. Here’s what they had to say.

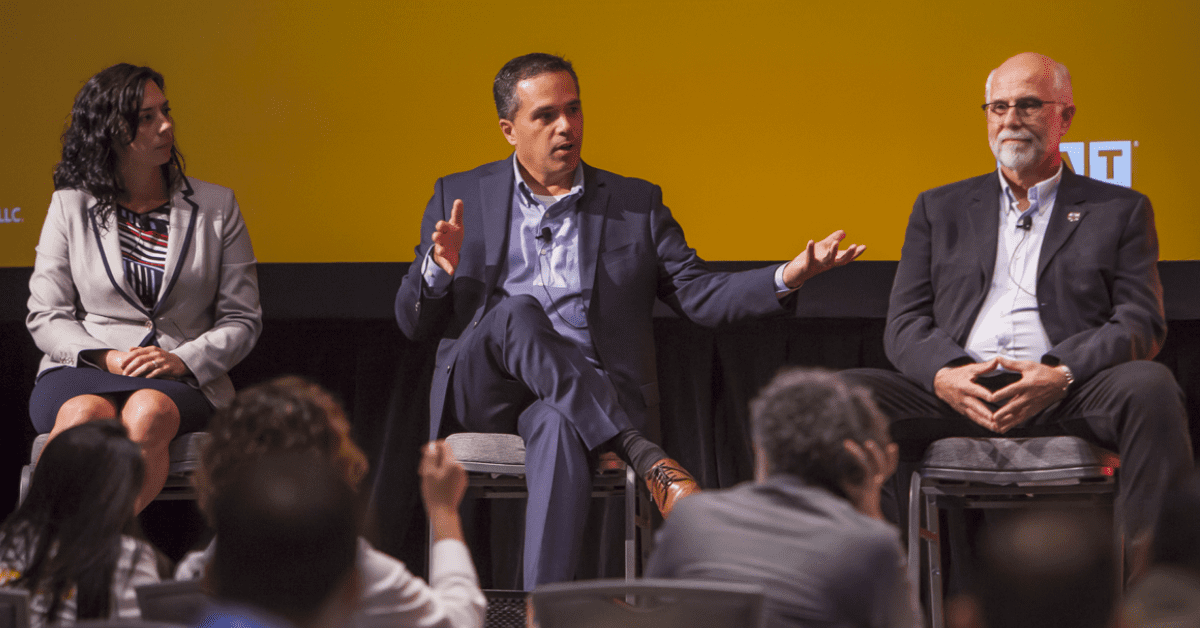

From left to right, Cori Purrington, David Domencic, and Gerald Hahn during a panel discussion at the DAT User Conference.

“The key is to be flexible. Especially with the ELD mandate, we need to inform our suppliers and distribution centers that their receiving hour window may no longer be conducive to transporting freight. If you’re not flexible in making appointments that fit within the driver’s hours of service, you’re going to have trouble getting capacity. Plus, we don’t want to be the reason the driver misses his next appointment or doesn’t make it home for the night.”

– David Domencic, Senior Manager of Transportation Procurement, Armada Supply Chain Solutions

Based in Pittsburgh, Armada manages supply chains for some of the nation’s largest restaurant chains, with a focus on refrigerated and frozen foods.

“We’ve changed the ways we’re ordering product. In the past a lot of the delays were because we had to take product off the truck and sort and segregate it before we marked it shipped in full. Now we’re creating loads that don’t take as much time to break down. That makes it faster to turn around the driver.”

– Cori Purrington, Senior Director of Transportation, ES3

ES3 is a sister company of C&S Wholesale Grocers. Based in Keen, NH, ES3 provides warehousing, transportation and supply chain management services for food and grocery products, servicing 5,500 stores with a fleet of 2,300 tractors and 7,000 trailers.

“We know we need to be flexible — especially with the smaller carriers and owner-operators. They may tell us they can take the load if we allow a certain trailer type, or if we can change the date or the time of the pick up. We may pay a little more if we know they’re having trouble getting a backhaul. Sometimes we find that if we just make a little tweak, we open up a whole new depth of carriers.”

– Gerald Hahn, Carrier Administration Supervisor, Charter Steel

Headquartered in Saukville, WI, Charter manufactures steel coil, which is transported to customers’ factories on flatbeds or in vans. The product requires drivers to actively secure the steel with straps and racks, but not all drivers are willing or able to do that.