As the weather warms up, suppliers can expect the demand for fresh fruits and vegetables to spike, highlighting the need for real-time data and analytics to better determine rates and stay nimble during both predictable and unexpected ebbs and flows in demand and product availability.

The current state of the industry

- Unlike previous years, we’re seeing incredibly low rates impact the freight and logistics industries. In fact, in May of 2022, all rates – including contact and spot – were 42% higher than the index (an index that measures shipper spend with inflation and deflation over time) and, this year, rates are 24% higher than the index, half of what they were this time last year.

- For spot rates, specifically, in May of 2022 they were 45% higher than the index and, this year, they’re 16% higher.

The challenge at hand

Perhaps the biggest challenge of the produce season is that freight and logistics companies are at the mercy of the product, rather than consumer demand. Fruits and veggies are ready when they’re ready, which may or may not coincide with when consumers want them.

While many companies are prepared for this surge, it can be difficult to navigate the unpredictability of the product itself. Therefore, spot shipping becomes increasingly common – more of a when, not an if – and shippers must be prepared to determine rates and maintain relationships, all while keeping up with demand.

The solution to success

Shippers use two key tactics to keep up with the market, hedge decisions, stay nimble, and see success during an unpredictable produce season:

Tapping into data and analytics

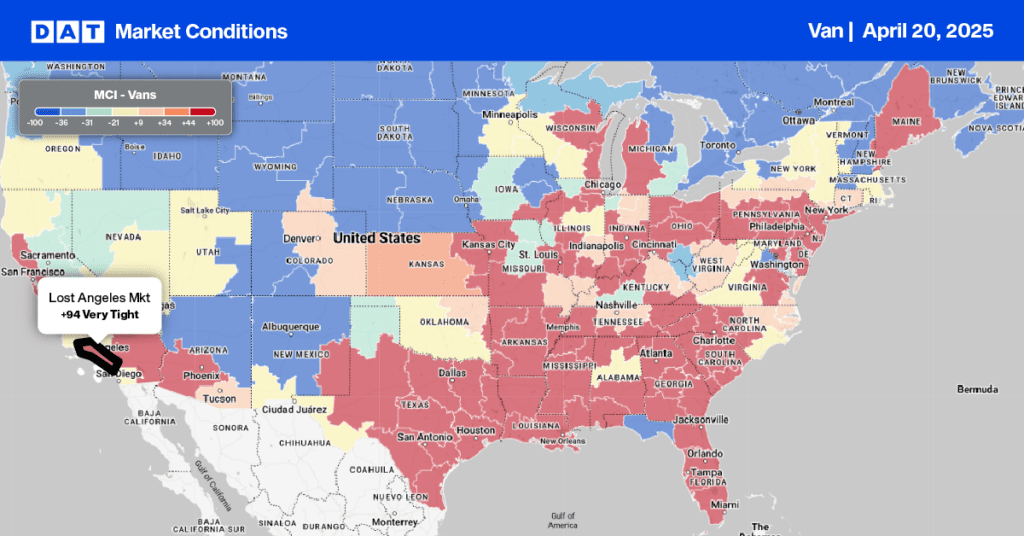

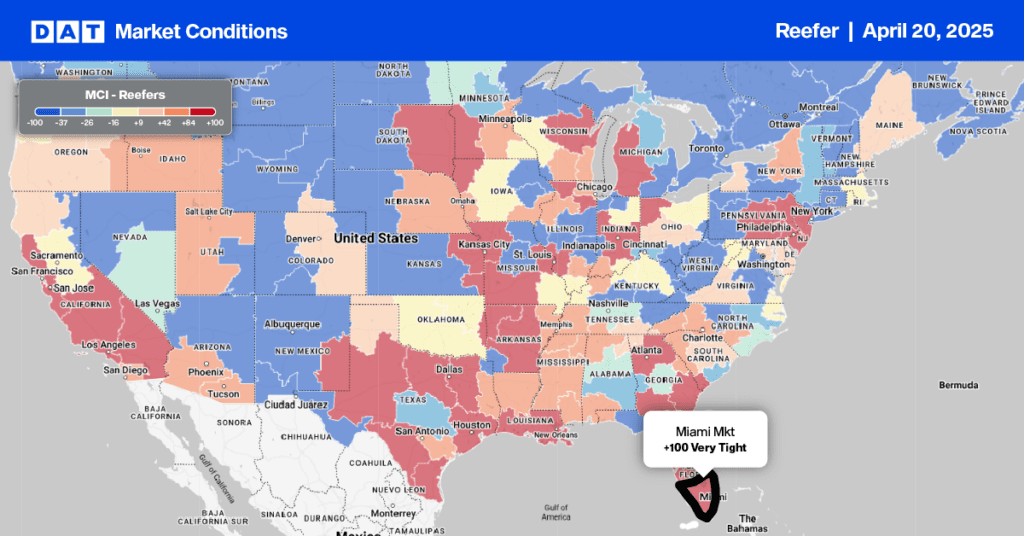

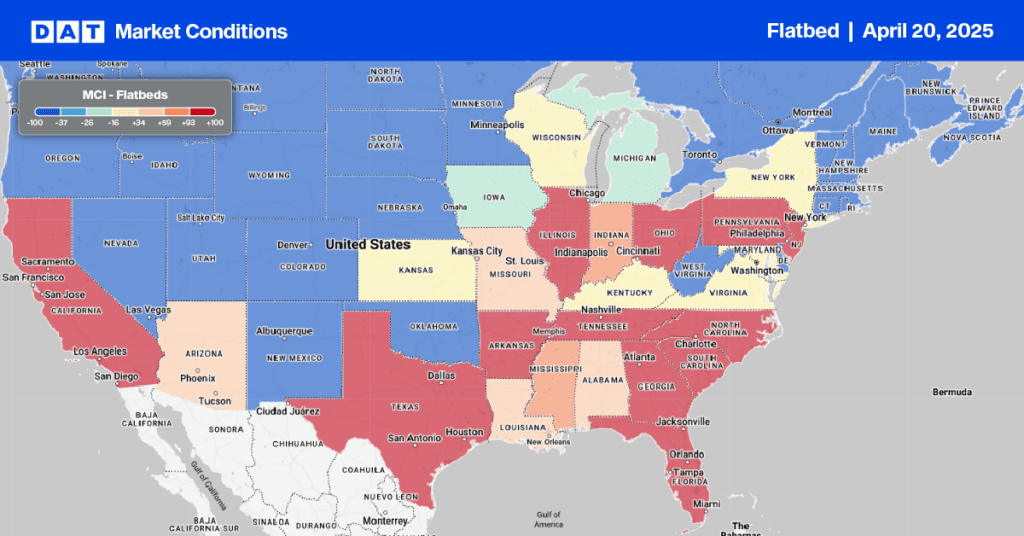

Perhaps the most important tool that transportation and logistics professionals can utilize to navigate produce season is data. Between historical, real-time, and forecast data, shippers have significantly more insight into where they stand relative to market rates, allowing them to drive more accurate and confident decision-making. Even more specifically, historical data allows shippers to plan ahead based on past trends, real-time data provides benchmarks that have increased transparency into exactly what is happening in the market at any given time, and forecast data helps shippers predict any market changes and plan for the future.

Plus, advanced analytics tools allow shippers to dial in their analysis to account for unique needs, such as filters or settings to specify equipment types, carrier requirements, and temperature control capabilities. Temperature control is particularly critical during produce season as getting freight from Point A to Point B quickly and efficiently to maintain freshness and quality is imperative.

With freight analytics, shippers can forecast and negotiate pricing for truckload services, assess seasonal and geographic demand patterns for trucks, evaluate the cost-benefit of procuring equipment for short-term storage, gain access to non-contract truckload capacity, and see the status of loads from dock to dock. All together, this information helps shippers improve inbound shipment scheduling and dock efficiency, aspects that are integral to ensuring the quality of produce in transit.

Especially in conditions when rates are low, having access to data is critical to ensuring shippers are capitalizing on opportunities to capture cost savings while still meeting demand and ensuring mutually beneficial outcomes with partners.

Maintaining relationships

Additionally, with shifting markets, it’s critical that shippers build and maintain positive relationships with brokers and carriers. With long-standing, trustworthy, and favorable partnerships, it’s more likely that they’ll stick by you during tumultuous times.

However, creating and sustaining a good relationship requires more than just niceties. Data and analytics should play a key role in promoting and driving positive relationships as they provide transparency to all players across the board. When shippers, carriers, and brokers can collaborate using the same data source, this straightforward and unbiased data becomes the great equalizer that can help foster mutual understanding, drive more productive discussions, and ensure everyone is getting a fair rate.

Best practices to prepare for produce season

Without data, shippers are flying blind. Particularly with the unpredictability of produce season, past approaches to planning are likely not enough.

Shippers that are navigating this market should look to invest in freight analytics solutions that address modern transportation and logistics challenges. By doing so, they’ll be armed with the critical insights and resources that not only help them strategically plan and prepare for high-demand periods such as produce season, but also enable them to be agile when demand inevitably shifts.

Fortunately, DAT iQ offers solutions that provide shippers, carriers and brokers with the unbiased historical, real-time, and forecast data they need to navigate this tumultuous market, get product out in a timely manner, and ensure fair rates all around.