A driving career covering over 6 million miles hauling refrigerated freight across one of the hottest continents on the planet makes Australian owner-operator Bob McMillan well qualified to haul temperature-controlled freight successfully.

More importantly, driving millions of miles across the vast Australian Outback means he has had to carefully manage load temperatures and reefer motor maintenance – all three simultaneously. Hauling what’s known in Australia as a B-Triple (see above), which has 46 wheels, Bob has operated reefer motors for approximately 125,000 engine hours over 21 years, so who better to ask about the successful operation of specialized equipment?

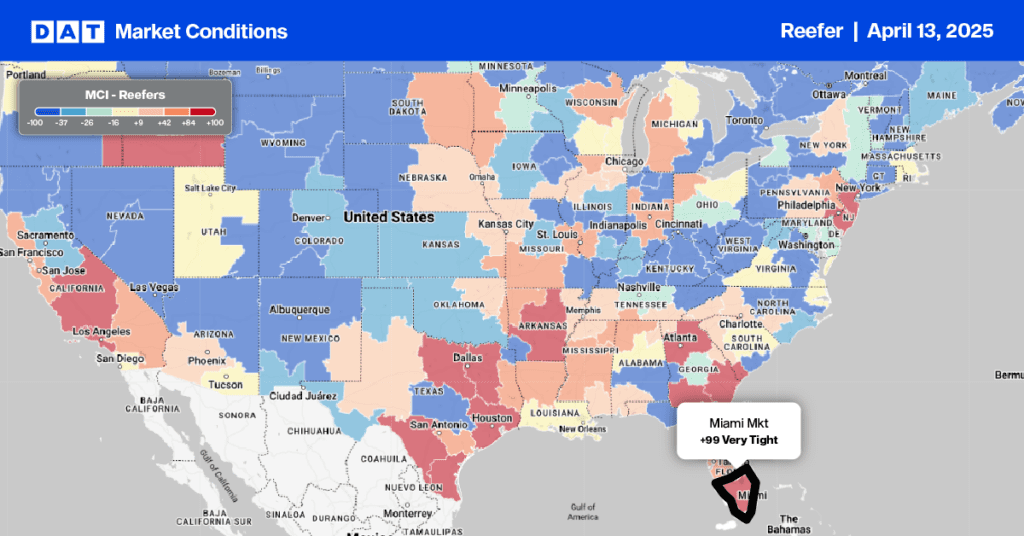

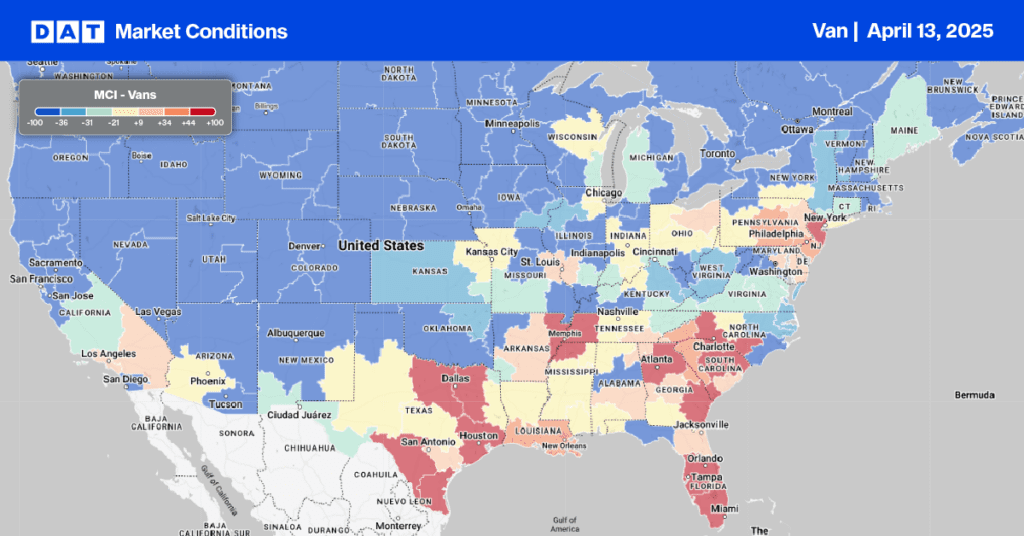

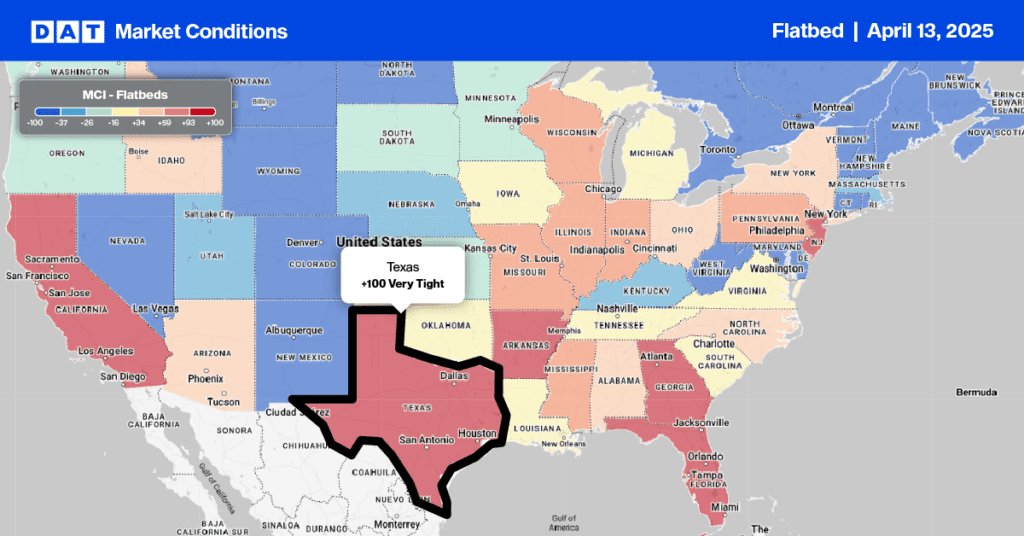

Get the clearest, most accurate view of the truckload marketplace with data from DAT iQ.

Tune into DAT iQ Live, live on YouTube or LinkedIn, 10am ET every Tuesday.

Bob McMillan’s top 10 tips for operating a reefer motor and hauling temperature-controlled loads

1. Spare Parts: Always carry extra belts, fuel filters, and air cleaner filters (whether you can fit them yourself or not), as you can’t always access the right part in an emergency.

2. Belts and Battery: Renew all belts every third, fourth or fifth full service depending on usage. Belts are cheaper than rejected loads:

- When it’s time to do a full reefer motor service, including an oil change and new filters, I always put new belts on regardless of their condition.

- Always ensure the battery is securely fastened in the cradle, keep battery terminals clean and protectively coated (a spray can is best), regularly check fluid level and battery indicator, and replace the battery before it fails completely.

3. Off Season: Always run your motor(s) for half an hour or so each week if you carry dry freight in the off-season.

4. Leaks: Check all lines for fluid and air leaks weekly.

5. Service Intervals: Recommended manufacturer service intervals are best observed also, and I recommend every 1,500 engine hours. Also, check for software updates to ensure the reefer unit runs on the latest version.

6. Gas: Ensure your reefer motors are always gassed up. Keep an eye on the steel ball in the window on your air receiver dryer. Gas levels are good if it’s at the top of the window.

7. Temperature Settings:

It would be best if you always used continuous cycle mode when hauling produce, not use cycle-sentry. Produce loads need continuous air flow to handle the heat of product respiration. Continuous airflow allows for a more consistent temperature throughout the trailer for the duration of transport.

Cycle-sentry should only be used for frozen loads in colder weather as they can handle more significant temperature variances without causing damage to the product.

8. Hot Loads: Loads that haven’t been pre-cooled are inevitable, and regardless of the set point, you’ll have to pull down the temperature as quickly as possible without damaging the product or reefer motor in the process. My best advice is to bring the temperature down gradually, not all at once.

- For example, if the set point is 46F and the load temperature is 60F, don’t set the reefer motor at 46F as soon as it’s loaded. Instead, put it at 55F initially and then every few hours, stop and drop the set point a few more degrees until you reach the desired temperature.

- I recommend this because if you try and pull down the set point too fast, the coil will freeze up. When that happens, the unit cannot cool, so the fan blows hot air as the unit recognizes the set point is being exceeded, so the reefer motor begins to rev higher.

9. Seals: Ensure your reefer trailer door seals completely and door hinges are not damaged.

10. Air Flow: on all produce loads, especially high loads like lettuce, where the grower always wants that extra row of boxes on top, make sure the air chute is not compressed, ripper, or torn. Improper air distribution will create cool and hot spots in the trailer resulting in load damage.

This list is by no means conclusive, but it is based on years of on-road experience. Keeping reefer motors well maintained and in top operating condition is vital to any carrier’s success in the temperature-controlled sector. It’s also great to consult your manufacturers’ warranty requirements, recommended service intervals, and best practices. Stay cool, everyone!