Developing a flexible and agile procurement strategy has always been critical to success in freight. However, the heightened market volatility of the past few years has put a spotlight on the process. Procurement teams are tasked with doing more while spending less as belts tighten and market pressures rise.

In a keynote session at CSCMP Edge 2023, Inam Iyoob Ph.D. explained the strategies helping today’s procurement teams optimize their networks and why third-party freight analytics are critical to their efforts.

Updating the Kraljic Matrix for shippers

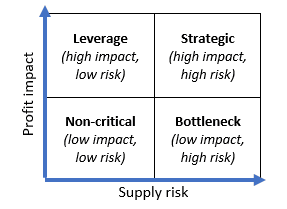

The Kraljic Matrix has been a staple for buyers since its inception in the 1980s. Kraljic’s method relies on two dimensions to categorize products or services into four categories:

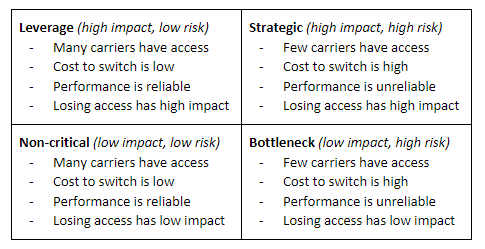

Though this model was designed to help manage purchasing for large enterprises, it can be valuable to shippers as well. With a few tweaks, it’s a useful framework for modern procurement teams. Rather than thinking about products or services, procurement teams can use Kraljic’s Matrix to categorize lanes:

Where a lane falls on the matrix gives insight into the procurement strategies most likely to support ongoing success.

Non-critical lanes

To optimize procurement for non-critical lanes, shippers may want to aggregate their carrier mix. This will help them gain leverage within a volatile market. They may also want to take advantage of dynamic pricing options, private load boards, and automated bidding.

Leverage lanes

Seeking medium to long-term contracts on these lanes will be beneficial and help shippers overcome volatility. Multi-round bids, target pricing, and multi-modal options will also be valuable for securing these important corridors. Shippers may also want to look into increasing their carrier bases and softening rounds of negotiation.

Strategic lanes

Since strategic lanes are high-risk, high-impact routes, shippers should aim to engage a carrier of choice to guarantee their access and terms. Developing balanced long-term contracts with core-carrier programs is key. Shippers may also look into securing separate pricing options for capacity changes, working with niche or regional carriers, or engaging dedicated fleets.

Bottleneck lanes

Standardization is key on bottleneck lanes. Though profit impact is low, the high volatility on these lanes means small changes can have big consequences. Engineering backhaul lanes, outlining dynamic pricing options, and having contingency plans for shipments on these lanes can all help shippers control spend and improve reliability.

Making sense of your matrix

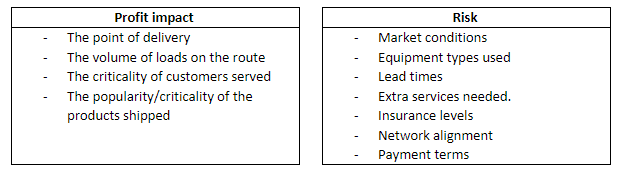

Once shippers understand how to adapt the Kraljic Matrix for their needs and the strategies that support success for each category, they can begin the work of assessing their networks. To determine where lanes fall, shippers should consider factors like:

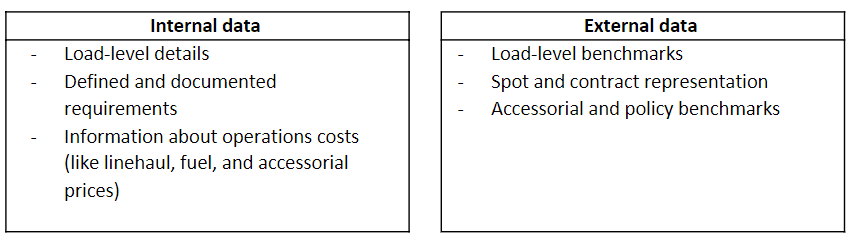

Of course, to accurately assess these factors, shippers need insight into their performance and the larger market. At minimum, shippers need to have access to:

Any other available metrics that speak to a lane’s risk or profit impact can be a part of the team’s considerations. The more diverse the datasets, the more clarity shippers gain about where the lane stands and what strategies will help them ensure success.

DAT IQ’s shipper solutions can help procurement teams get the insight they need to guide their assessments. To start your procurement optimization journey, connect with one of our experts today.