As news of severe droughts seems to be a yearly concern, some farmers are looking to technology for alternative ways of producing some of our nation’s favorite produce. Vertical farming is the practice of growing crops in vertically stacked layers. It conserves space while at the same time amplifying yield per square foot compared to a traditional farm field. The modern concept of vertical farming was proposed in 1999 by Dickson Despommier, professor of Public and Environmental Health at Columbia University. Despommier and his students came up with a design of a skyscraper farm that could feed 50,000 people. However, the origins of this type of farming date back nearly 2,500 years ago to the Babylonians and, more recently, 1,000 years ago to the Aztecs, who pioneered the usage of hydroponics which is key to vertical farming.

Arid countries such as the UAE have embraced this technology, and its popularity is growing quickly in the United States. As a result, Muncie, IN, will be home to a new vertical farm warehouse and possibly the largest in the country. Living Greens, Inc. has acquired a 200,000 sq. ft. warehouse in Muncie with a footprint of about three and a half football fields. Living Greens began 11 years ago, and it spent the first eight years focusing on research and development and acquired its patents, and three years ago launched its first farm in Minnesota on a 20,000 sq. ft. site. The new site equates to about 4.6 acres, but by going vertical, it will grow as much produce as 200 acres on the ground.

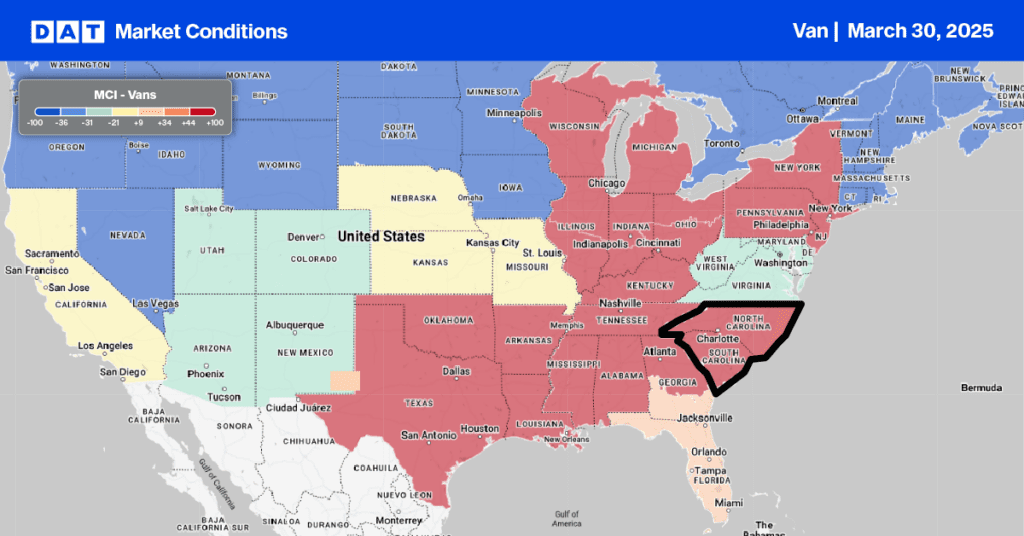

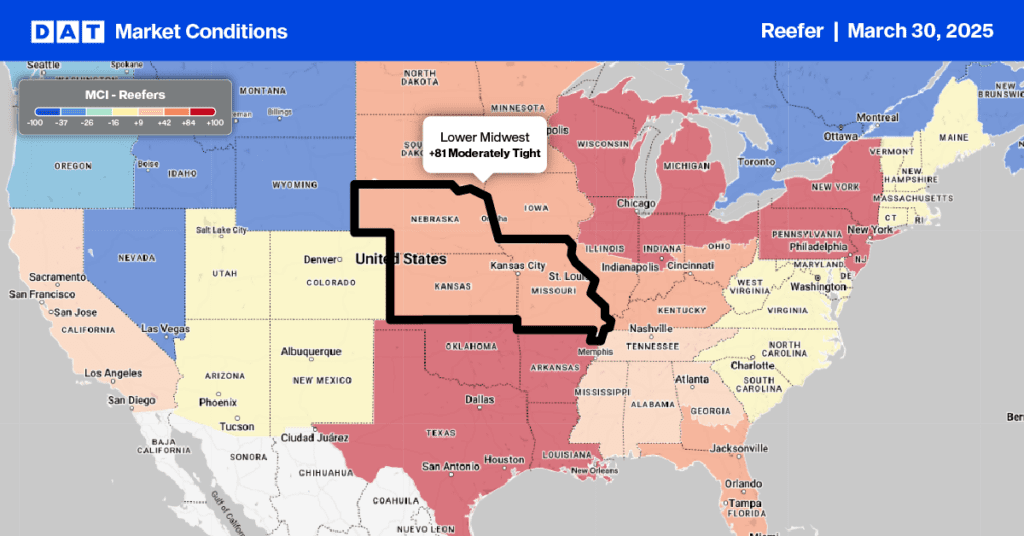

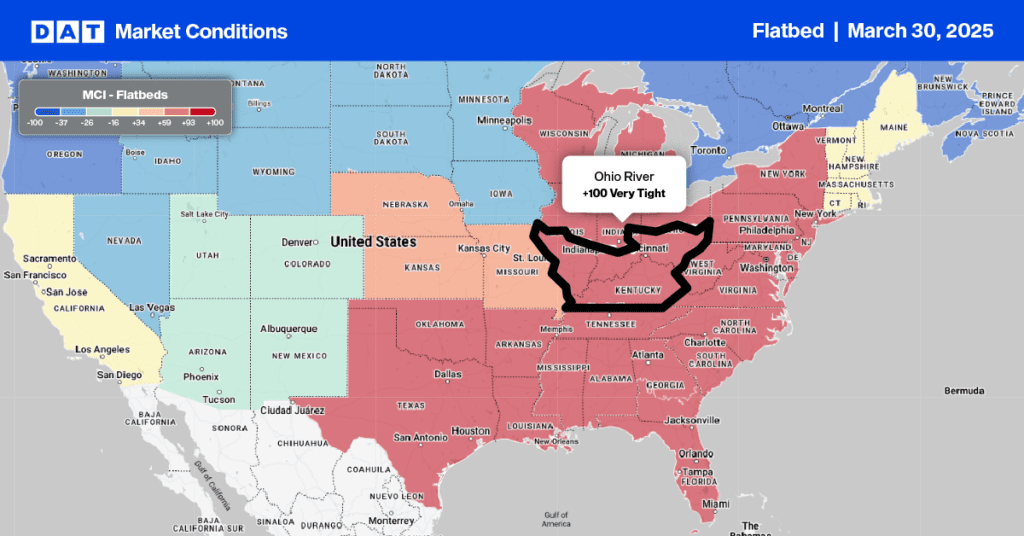

Get the clearest, most accurate view of the truckload marketplace with data from DAT iQ.

Tune into DAT iQ Live, live on YouTube or LinkedIn, 10am ET every Tuesday.

Vertical farming doesn’t work for all crops and is best suited for salad ingredients. Living Greens plans to grow a wide range of leafy greens, including iceberg, romaine, butter, leaf lettuces, cabbage, spinach, bok choy, and kale. The farm expects to produce about seven million pounds of leafy greens yearly. George Pastrana, the president and CEO of Living Greens, said he knows of other indoor farms — such as greenhouses or single-layer hydroponic systems — that cover more acres. “But in terms of yield,” he said, “ours will be the biggest in the U.S. that I know of.”

The primary methods used in vertical farming are hydroponics and aquaculture, where the plants are grown in water and fish supply the nutrients through their waste. Living greens also use aeroponics, in which the plants are grown in the air. The seedlings are transplanted to vertical shelves, and a canopy of roots and vines hangs down. Those roots are misted regularly with a water solution imbued with nutrients. Then, those plants are harvested in just a matter of weeks, not months.

Living Greens will also use less water than a traditional farm: “We are much more efficient with water usage because we recycle it,” Pastrana said. The vertical system will use only 5% as much, collecting and condensing any of the mist not soaked up by the roots.” Other advantages of vertical farming are that no fertilizers or pesticides are used, and the weather is not a factor with produce that can be harvested year-round. However, one of the most significant benefits is that vertical farms can be located closer to population centers. Nearly all leafy greens consumed in the U.S. are grown out west in California, Arizona, and New Mexico. Vertical farming allows for produce that is harvested and on the store shelves within 24 hours and much quicker transit to other nearby population centers. Indoor agriculture can work particularly well in areas that aren’t suited for traditional farming areas with poor soils or too hot or cold all year. The vertical farming market is expected to grow exponentially this decade, which may lead to new shipping patterns for refrigerated carriers that have traditionally hauled the leafy greens from the southwest.