August is the highest-shrink month for produce due to many factors: excessive heat, mature fruit, overordering, and overstocking. As one director once said, “It’s the busiest time of the year, and with vacations to cover, it’s often staffed by the least-experienced clerks.” You can’t eliminate all shrink, but by keeping an eye on the critical control points, you can at least minimize the impact, according to Amand Lobato at the Idaho Potato Commission.

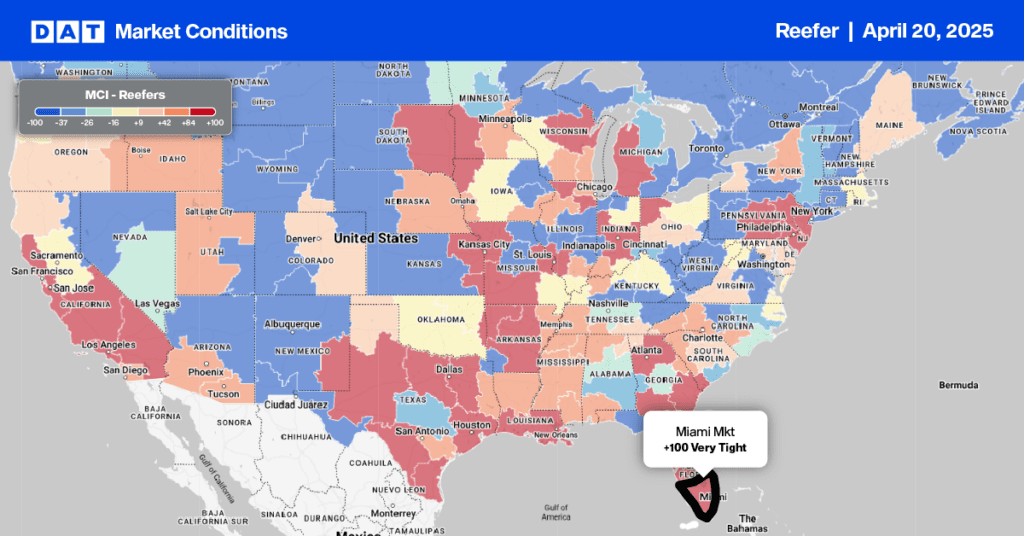

According to the USDA, national truckload produce volumes are around 5% lower than last year and have dropped by around 20% since the July 4 peak in shipping volume. Reefer carriers can expect softer produce volumes until Thanksgiving starts to improve demand, but until then, we will see some of the lowest produce volumes in the last decade.

Amand recalls a store manager once called in a panic. “Please get out here as soon as possible,” he said. “My produce department came in four points below average, and his shrink is too high. I think it’s due to not marking down enough distressed products.” Amand wasn’t surprised as the store showed a history of increasing shrinkage since the new produce manager began just a few months prior. It was the manager’s first store. His crew was not well seasoned, and the month prior was August — historically the highest-shrink month in the produce aisle.

After 40 years of experience in the produce business spanning a range of food service and retail positions, he advises businesses to focus on critical control points, which determine the successful outcome of sales, gross profit margin, stock levels, and keeping shrinkage in check.

Among these points are:

- Ordering: This is the single-biggest control point to focus on to minimize shrink. Order only what you need until you receive your next delivery. Sales are important, but take caution to have only minimal safety stock on hand above your usual sales projections. It’s easy to overorder, which creates shrink. So, don’t. Keep the inventory tight!

- Maintaining the cold chain: Never allow a new load to sit idle on a warm dock. Break down the load upon arrival. Keep the cold items cold and the ambient-temperature items separate. If items need refrigeration, do everything you can to store and merchandise them to protect your investment. Keep the wet rack misters adjusted properly.

- Rotation: Follow the FIFO (first in, first out) philosophy. Rotate produce in the cooler and backroom daily and ensure that, as much as possible, every stocking includes a plan to rotate and cull carefully.

- Training: Consider training a constant endeavor. Teach your charges to process and stock produce correctly to minimize damage, prevent over-trimming, and stress careful product handling. Check off your receiving invoices and report any discrepancies. Divert distressed produce to your salad bar or outlying departments while it is still usable. The object is to ensure that produce leaves the store intact in a shopper’s cart.

Merchandising and space allocation: Spreading out is always better than stacking high, which can create shrinkage. Allocate according to selling power and seasonality so that each display can turn or completely sell through at least once daily.