It’s great to ask why ocean carriers continue to send ships to the overburdened ports of Long Beach and Los Angeles. While it’s a complex answer, it predictably results with the problem getting worse before it gets better.

Get the clearest, most accurate view of the truckload marketplace with data from DAT iQ.

Tune into DAT iQ Live, live on YouTube or LinkedIn, 10am ET every Tuesday.

According to The Marine Exchange, a record 95 container vessels are in port this week, of which 62 are “at-anchor” waiting on average 9.5 days to dock and unload. Of those “at-anchor” ships, 40 are anchored and a further 22 are in “drift areas,” literally blowing in the wind. Some are even adrift outside the 20-mile arrival timeline as congestion worsens.

Compared to this time last year, at-anchor vessels average one to two days at most. But as import volumes started to surge this time last year, we ended up with what was then a record-high 40 vessels waiting to unload at the start of February.

Just six months later and with the queue growing daily, we soon may see double that number, delaying thousands of containers of much-needed freight in the process.

This year’s peak-shipping season comes ahead of an expected record consumer retail shopping season. Consumers flush with cash and a burning desire to shop are eager to spend big… again. This year might be a little different though. It’s not for lack of demand, but a broken supply chain that has never fully recovered from March 2020 when there was a historic ‘pantry-stocking’ buying frenzy just after pandemic shut downs were announced.

In a recent Journal of Commerce article, marine shipping expert Lars Jensen wrote a great article about the worsening crisis on the West Coast and why shippers will continue to add ships to the port queue:

“What instead happens is that as congestion has been constantly worsening day by day over the last two months, shippers are increasingly eager to get cargo loaded in Asia. The — again rational — view being that the cargo is highly likely to be delayed, and therefore it would be better to ship the cargo earlier than usual to still get it to arrive on time.”

Jensen also adds:

“This ramps up short-term demand, and the need for more vessels, and in turn makes the problem even worse. At the end of the day, we end up with the bottlenecks we now see. And the carriers will not be able to resolve the bottleneck. The resolution here is much more tightly linked to the inland situation — getting the cargo to the port is of no use until there is sufficient truck, chassis, and rail capacity, as well as warehousing space to move the cargo away from the ports.”

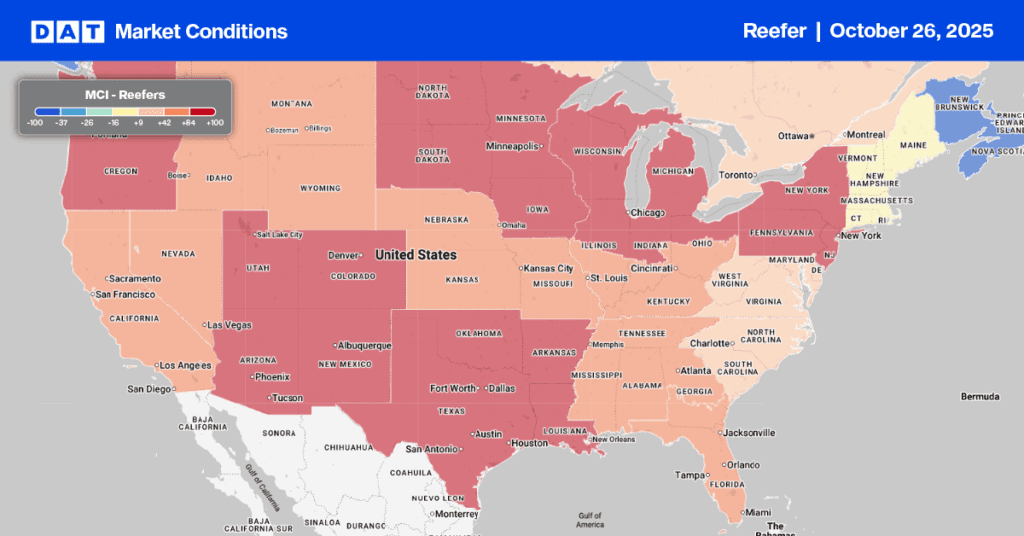

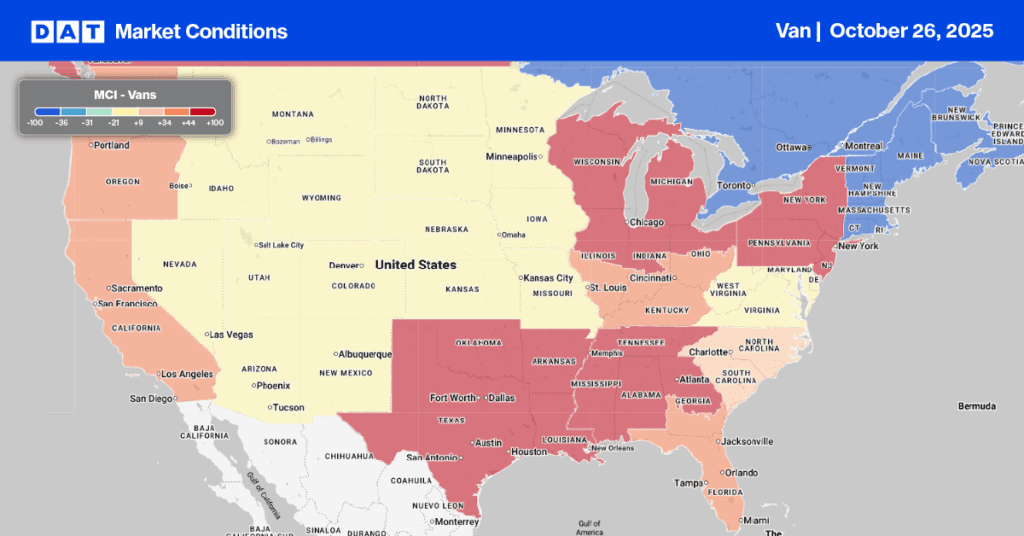

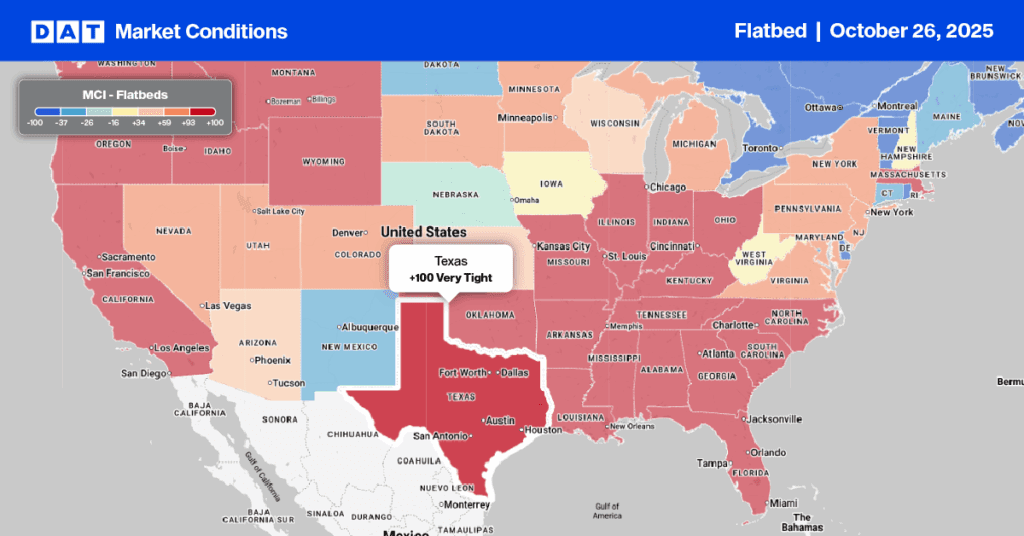

For the rest of this year at the very least, DAT expects to see very tight truckload capacity in high-volume ports where congestion exists. Over the last 12-months, we’ve been observing a strong correlation between imports and spot market load volumes on a one- to two-week lag with corresponding upward spot rate movement.